-

Coat Resist Point Level Switch

RF Admittance Point Level Switch

We are Manufacturer, Supplier, Exporter of Coat Resist Point Level Switch. This product is also known as Coat-Resist Point Level Switches. Our setup is situated in Pune, Maharashtra, India.

COAT-RESIST is a compact point level switch with integral electronics, based on RF Admittance measurement technology utilizing a three electrode design with active shield compensation. It is superior in performance to conventional capacitance based systems that often suffer from false level detection due to service material adhering to the probe electrode. It offers a satisfactory solution in tough environments where service material has a tendency to coat, where there is bridging (build up) of material between the probe electrode and side wall of the vessel, where, material particles having electrostatic charge float in the vicinity of the sense electrode, and the vessel internal temperature is high. Such environments are often encountered in electrostatic precipitators wherein no other instruments are suited. The instrument has a built in discharge device to protect it from damaging effects of static electricity.

Salient Features:- Not affected by material build up on side walls and coating on probe

- Protected against frictionally induced static charge due to material movement in the vessel

- High sensitivity so operates reliably in low dielectric materials like Fly ash and Plastic chips

- Bar graph LED display for ease of calibration and material trend indication

- Built-in Universal switched mode power supply for AC / DC operation

- Field selectable Fail-safe mode for High and Low level operation

- Field adjustable switching delay for probe covered and uncovered condition

- Robust in construction to withstand the rigors of plant environment

- High temperature versions available on request

- Various mounting arrangements available to suit customer needs

- Remotely mounted electronics version also available on request

Operating Principle

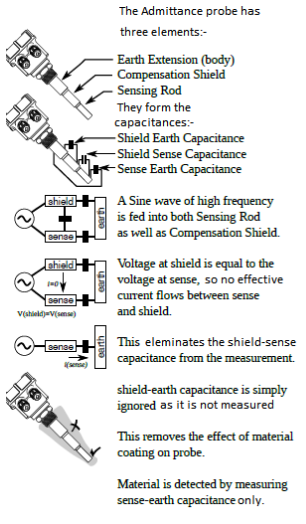

The probe comprises of three elements; Sense, Shield and Ground electrically insulated from each other by means of suitable insulators. The Sense element and the vessel wall (Ground) serve as the two electrodes of an electrical capacitor with the service material as the dielectric. A change in material level causes a change in the Admittance which is measured by the electronics. A Radio frequency oscillator generates the measuring frequency. An impedance transforming shield isolation amlifier is used to drive the shield actively to maintain the equipotentiality between the probe and shield electrodes thereby immunizing the probe from build up and coating. For clarity please refer to the figure on the left.

Applications :

Level limit detection of fine, coarse, solids of low dielectric constant that have a tendency to stick coat and develop static charge at high vessel temperatures and in bulk material handling. Can be used for level detection of powders, sand, sugar, pulverized coal, food grains, cement, stones, gravel, flyash, bed-ash, clinker etc. Coat-Resist finds use in cement plants, power plants, ash handling systems, soap and detergent plants, paints and emulsion plants etc.

Technical specification

Housing Cast Aluminum weather proof powder coated

Cable entry

2 Nos. ½” BSP / NPT

Cable gland

2 Nos. Single/ Double compression size

1/2” BSP / NPT / Brass / Stainless steel NG20Tolerable ambient Temp

0°c to 60°c

Power Consumption

5VA approx.

Mains supply

90 to 265 V AC, 50 / 60 Hz or 18 to 55 V DC

Fail safe mode

High / Low field selectable

Outputs

One/two sets of potential free c/o contacts

rated at 6Amps 230V AC 50 Hz for non inductive loads or

Open collector PNP output limited to 100ma max at 24V DCIndication:

Red LED for alarm

Sensitivity and material

trend Indicator

Ten step Bar display

calibration

Through multi turn potentiometer

Response Time

0.2 Seconds typical

Switching delay

Adjustable up to 20 seconds (covered & uncovered)

Switching Hysteresis

0.2 Pf Typical